IDEAL FOR SMALL, COMPLEX SHAPES

INTRODUCING OUR LATEST HIGH-SPEED

BLANKING SYSTEM

Master Blanker entry model "BLH"

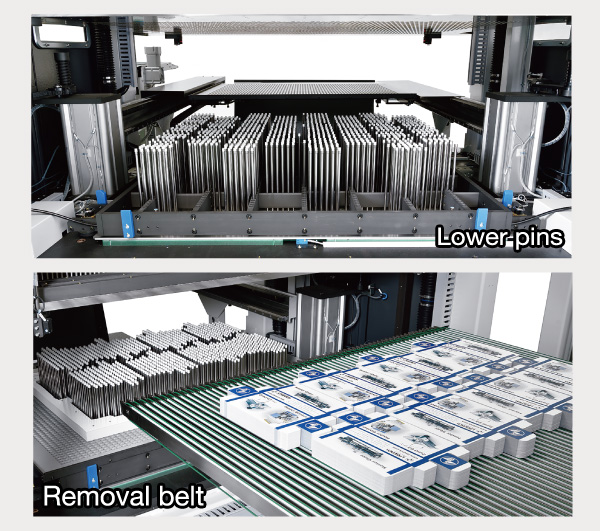

We have shrunk the 14 mm diameter used for the upper pins in our conventional models to just 9 mm and also refined the pitches for the upper and lower pins to, respectively, 14 x 14 mm and 17 x 15 mm. This enables the BLH to handle workpieces with even smaller and more complex shapes, dramatically increasing blanking accuracy. The removal belt also features a new design with a narrower comb width, which ensures stable transport of even small workpieces. The unloading belt has likewise been improved to provide better stacking accuracy.

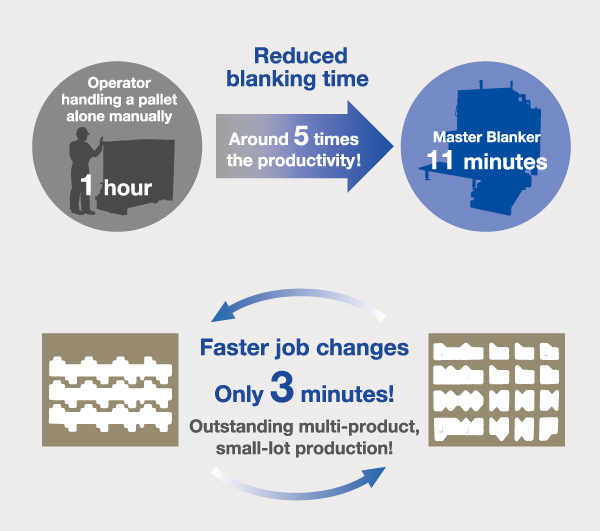

The BLH delivers improved waste removal that is five times faster than manual production. A single cycle now only takes around 40 seconds, meaning an entire pallet of around 1,400 mm high can be processed in just 11 minutes. Changeovers between jobs also require as little as three minutes. These features enable outstanding productivity even for high mix, small lot work. After blanking, workpieces are also stacked automatically, ensuring major improvements in efficiency throughout the entire workflow.

Air cylinders are used to improve holding of workpieces during blanking. This reduces slippage to an absolute minimum, enabling blanking of plastic materials such as in-mold labels plus small products.

With our conventional models, blanked workpieces are placed on three separate belts for loading onto pallets. The BLH features a completely new design with a single integrated belt. This system significantly improves stability during transport and enables more precise loading onto pallets.

The BLH is equipped with a centrally located touch panel for performing operations. Almost all processing can be controlled using this panel, greatly reducing an operator's workload. The display also features a clear and intuitive button layout and color scheme that helps to prevent errors.

Blanking System

Eliminates paper dust

Single person operation, cost saver

Contact