SIMPLE OPERATION,LABOR SAVING

BLANKING SYSTEM

Master Blanker mid rage model"BLK"

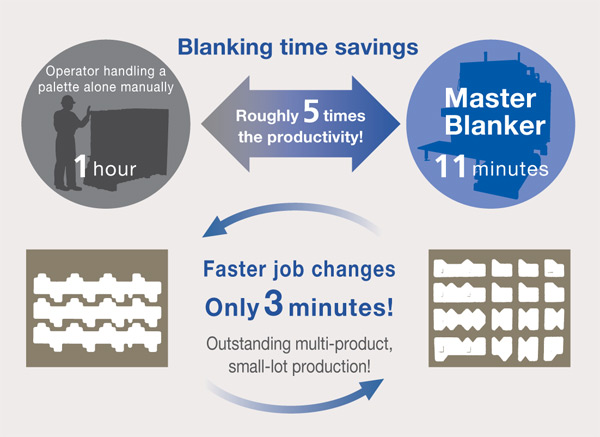

One pallet is completed in 11 minutes.4 to 5 pallets (14,000 to 17,000 sheets) per 1 hour.

This calculation is based on paper thickness of carton board as 0.4mm.

BLK saves 3 to 4 workers.

These productivity may change depends on job.

The Master Blanker quintuples waste removal processing efficiency.Since it can perform blanking of materials up to 85 mm thick in a cycle of roughly 40 seconds, it can process an entire pallet (about 1,400 mm tall) in about 11 minutes. What's more, it only takes three minutes to complete the job change process. The Master Blanker truly breaks the mold when it comes to multi-product, small-lot production.

The Master Blanker features a unique arrangement of upper and lower pins. Since expensive male/female blanking boards are not required, running costs are dramatically reduced. The Master Blanker features easy operation for everything from blanking to changing jobs, so a single operator can handle the unit.

The Master Blanker also saves both the labor and the time that used to be required for manual waste removal operations.

Conveyor delivery is option for workers to pick up each blanks, either with or without palletizing system.

Blanking System

Eliminates paper dust

Single person operation, cost saver

Contact